uniTank

uniTank

uniTank is fast

Turns 3D scans into answers in less time.

uniTank is designed for storage tanks

Assesses standards compliance with API 650, API 653, and API MPMS 2.2.

uniTank is all you need

Incorporates registration, classification, analysis, and reporting all in one single package.

Scanner Agnostic

Scanner AgnosticuniTank works with all the common laser scanners out there. It accepts point clouds in any of the generic formats (E57, PTX, PTS). uniTank even comes with a tool that shows you how many scans you need and where to place them. Based on our extensive experience with using laser scanning within the storage tank environment, this tool is optimized to maximize data quality in critical areas and ensures adequate overlap for registration.

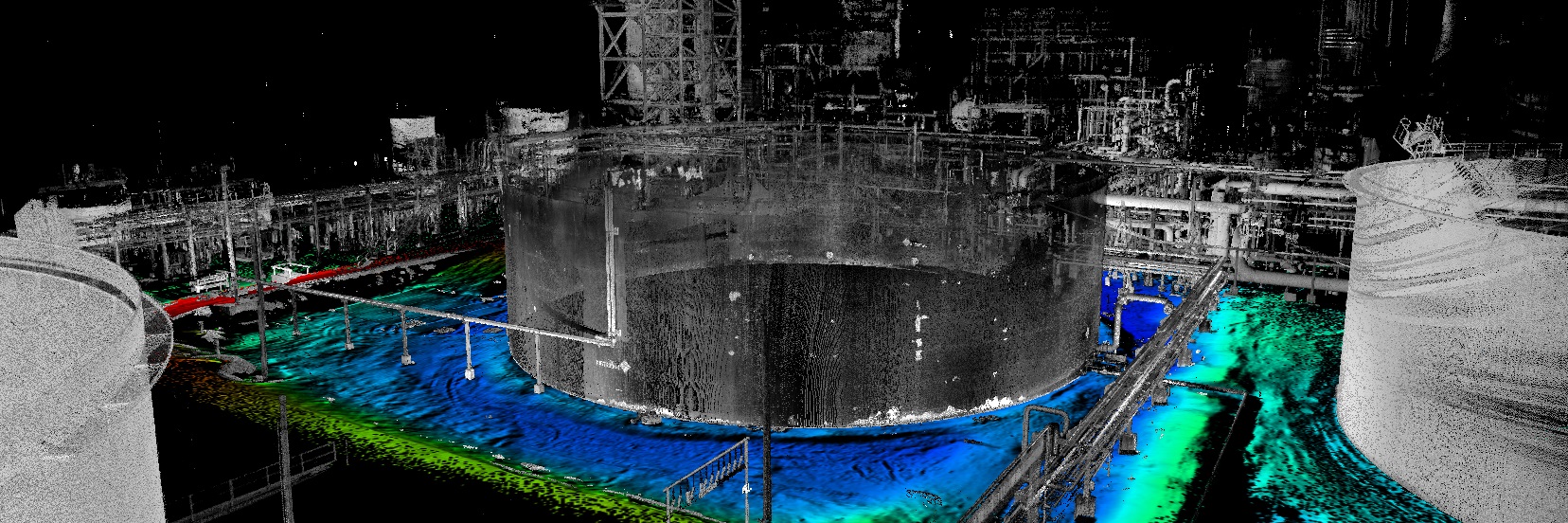

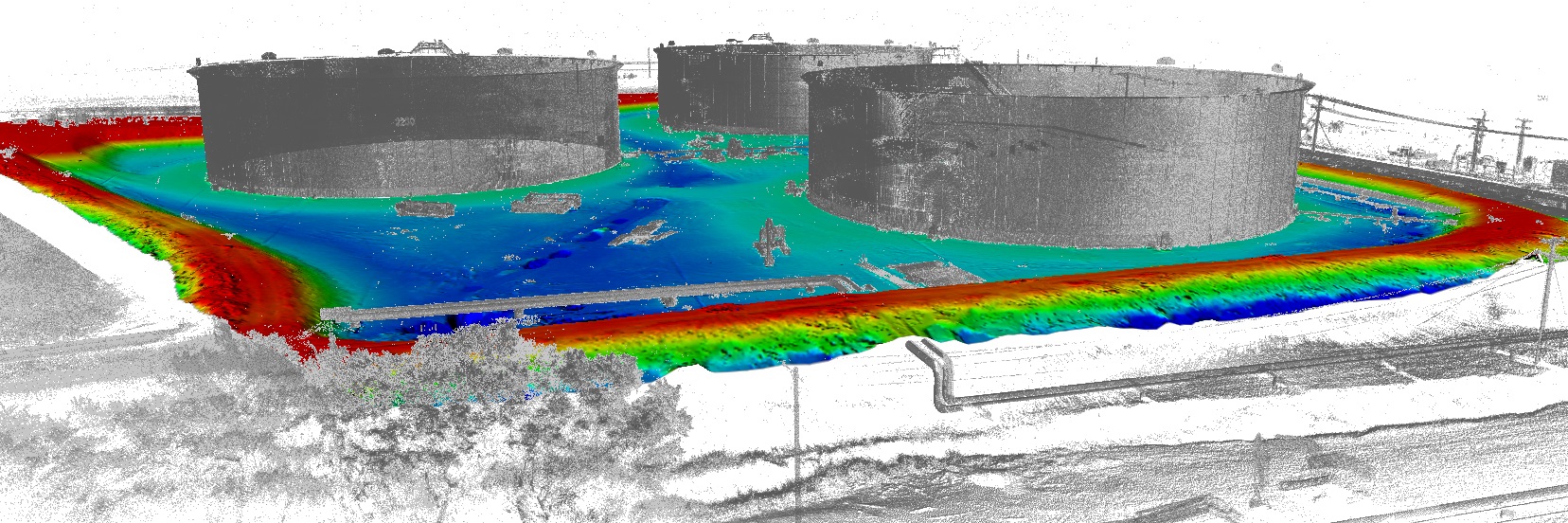

Registration

RegistrationOur cutting edge targetless registration system allows you to save time both in the field and in the office. No longer do you need to carry bulky spheres with you on the plane or tape up targets only to have them fall off as you scan. Our advanced registration algorithms can achieve unmatched accuracy in less time with less hassle, even in the most adverse situations.

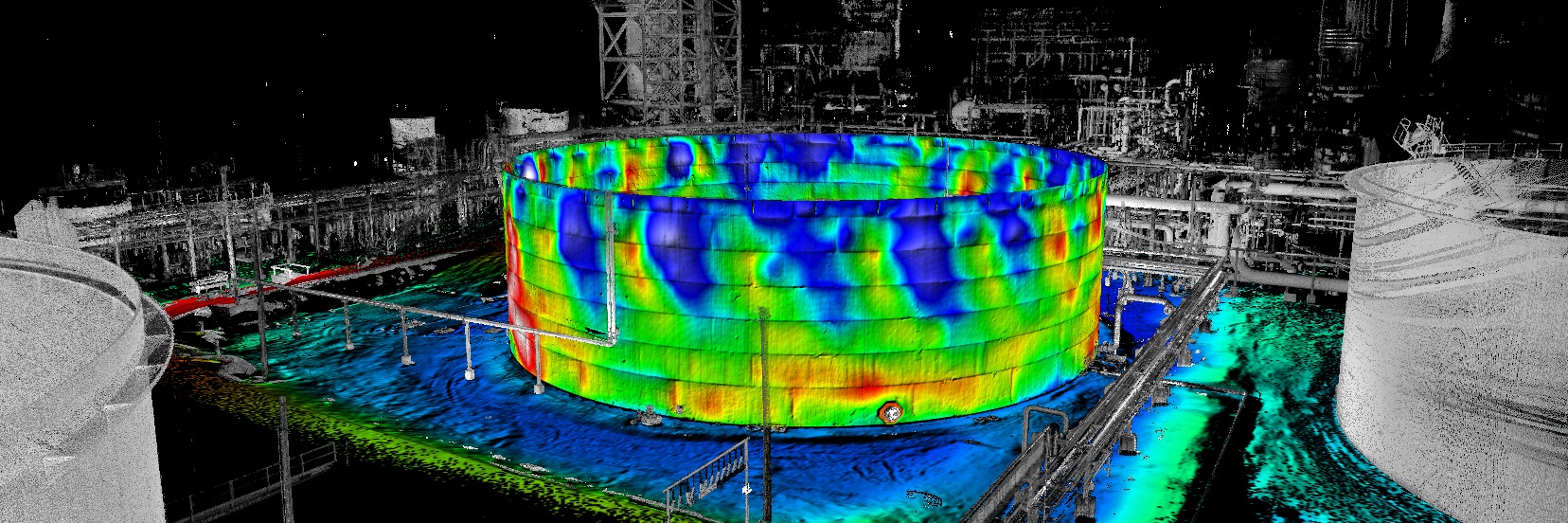

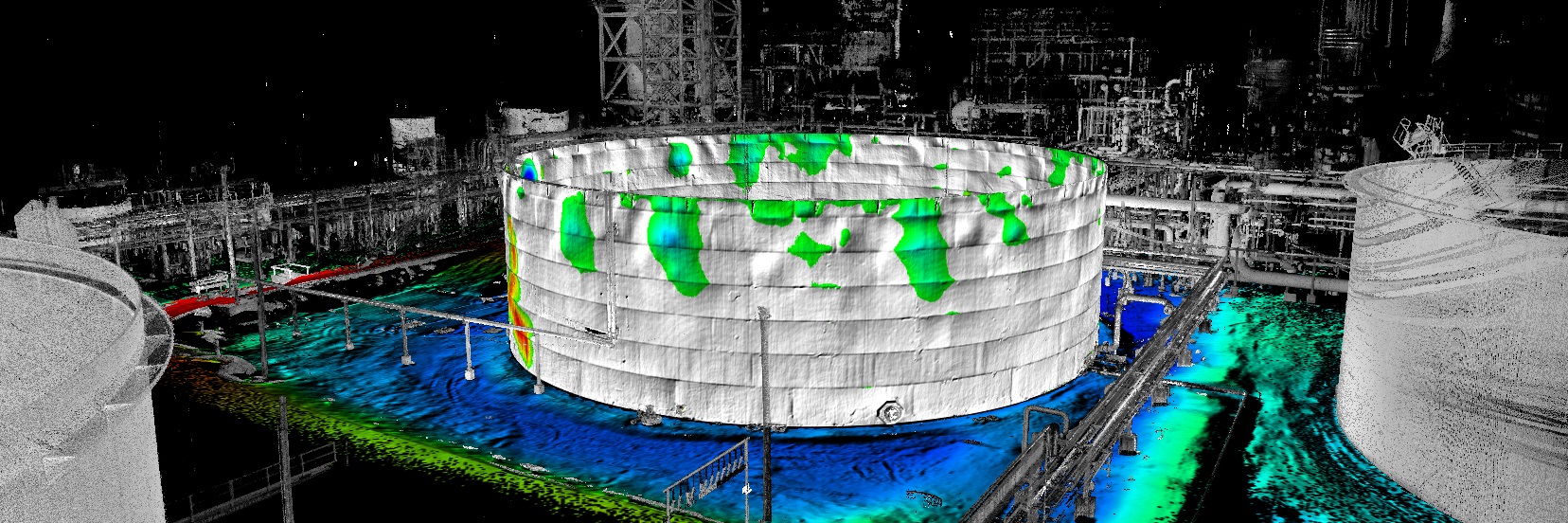

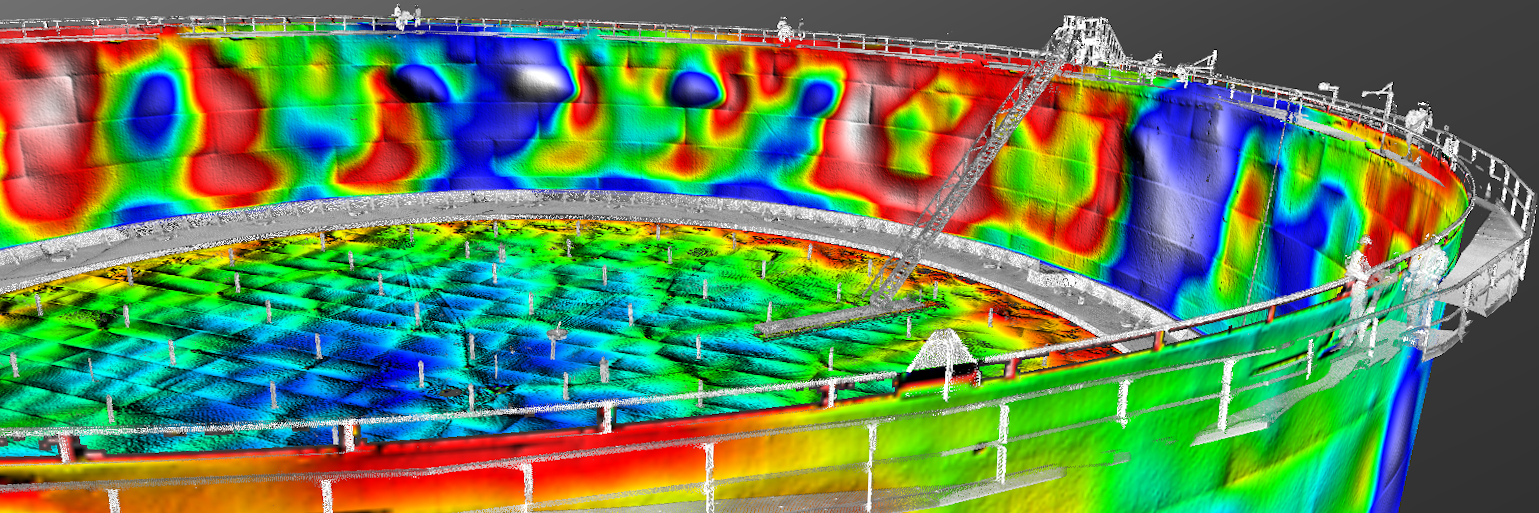

Classification

ClassificationOur automated classification tools are fine tuned for storage tanks. So rest assured, we can find all your tank parts quickly without having to muck around point by point. Poorly classified data can lead to embarrassing results, so don’t let that happen to you!

Standards Compliance

Standards ComplianceIntegrated standards compliance assessment for settlement, verticality, roundness, strapping/calibration, secondary containment, and more (API 650, API 653, API MPMS 2.2). We have been at this a long time, so if there’s a tool you need, we probably have it.

Customizable Reports

Customizable ReportsOur automated reporting module allows you to customize your reports using templates, so they come out just the way you like them, every time. Need a different flavor for each customer? Make as many templates as you need! Don’t waste your time putting your reports together by hand and risk inserting the wrong chart in the wrong place. Let us do the heavy lifting, we’ll get it right, guaranteed!

2-way Workflow

2-way WorkflowWhy is a single software package better? Simply put, you can step backwards in your workflow. There are two significant advantages to this:

Continuous Improvement

Continuous ImprovementCan’t find what you’re looking for? Make a request to our development team and we’ll try to fit it into our next release cycle. uniTank is the same software we use internally to inspect hundreds of tanks a year. So if there’s a tool that will benefit you, it will likely benefit us too!

Customer Service

Customer ServiceUnlike other software vendors where you send your requests and grievances into the void, we listen to your input! Many of our new features are a direct result of customer feedback and requests. We can only get better with your help. Just hear what our customers have to say:

"uniTank has streamlined the process of tank evaluation, saving us a lot of time."

Susan Marie Wenner, Baker Consulting Group, Inc.

"Very user friendly software, and the technical support is second to none. They go far and beyond to help the client with their needs."

Ricky Seydel, Gauge Point Calibration, Inc.

"Since using Novlum uniTank our process for analysing Tank compliance to applicable API’s has been streamlined. Our time spent using conventional methods has been made more efficient and the team at Novlum are extremely helpful with any question always taking the time to run a tutorial or analyse data for us to get us up to speed with any learning required. Novlum uniTank has allowed us to deliver comprehensive reports efficiently to meet client needs."

Luke Allen, WSP

uniTank as a Service

uniTank as a Service Don't have time to do it yourself? Let us do it for you!

Don't have time to do it yourself? Let us do it for you!